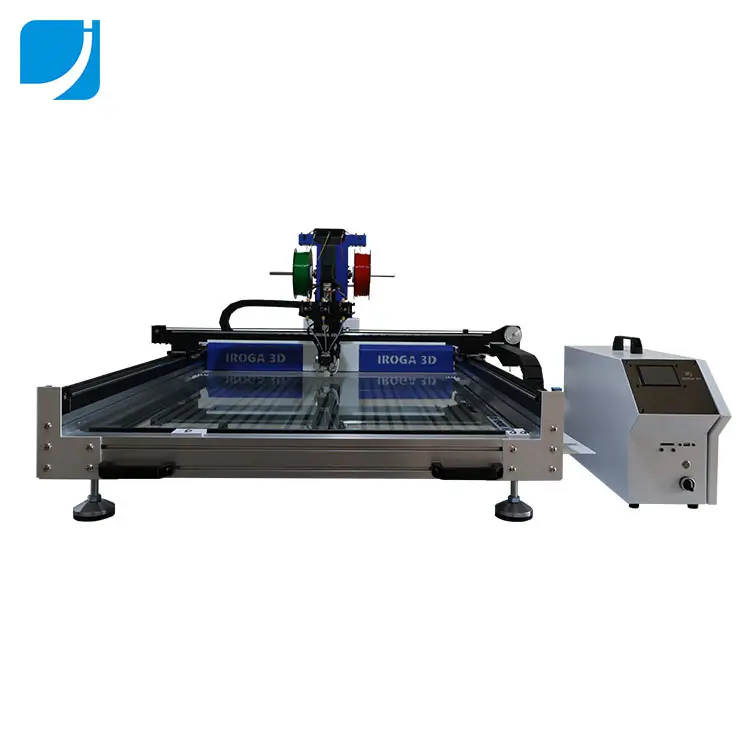

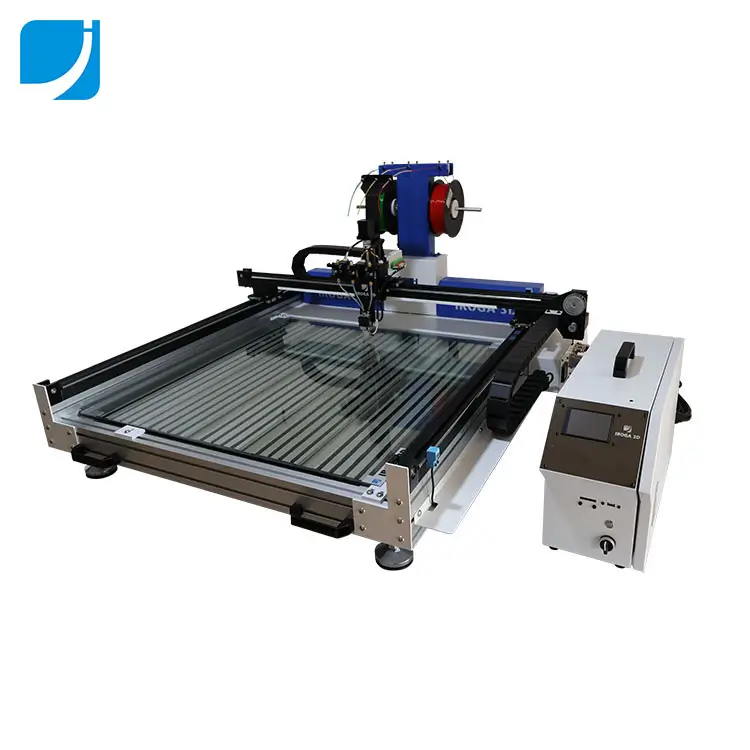

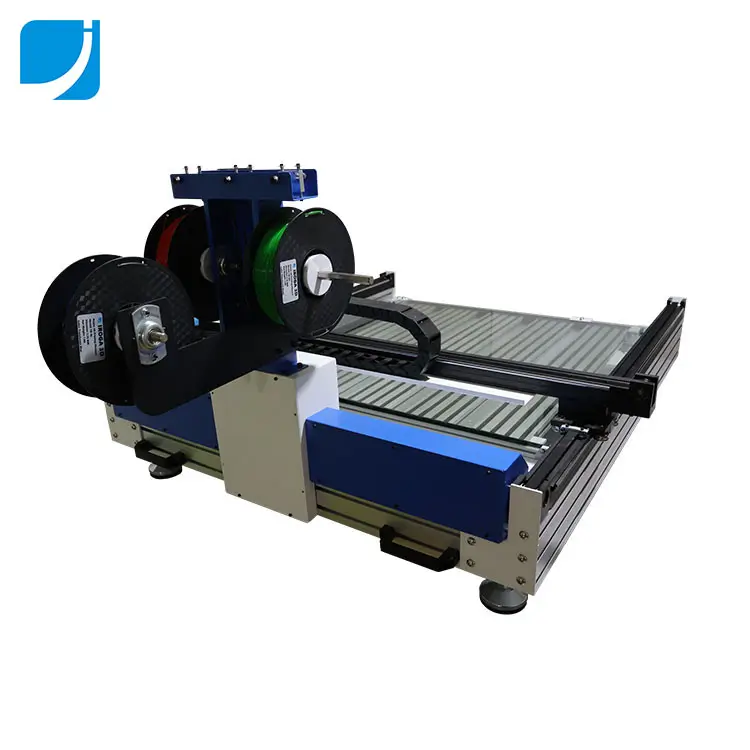

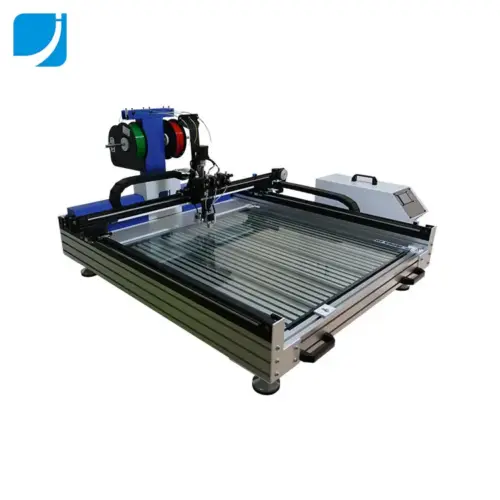

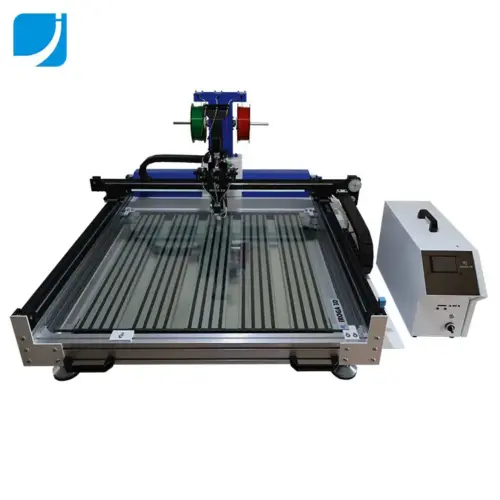

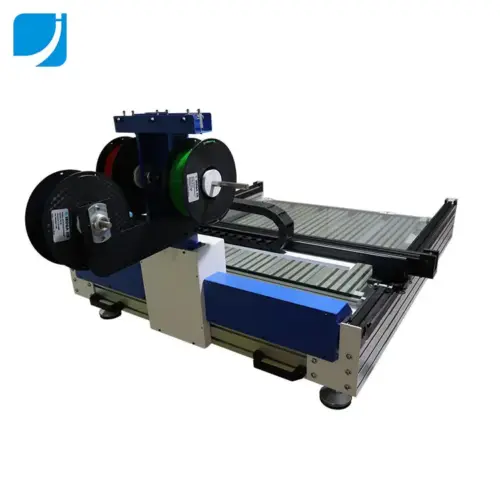

80cm Simple 3D Letter Printing Machine for Luminous Signages

Basic Information of 3D Letter Printing Machine for Luminous Signages

3D letter printing machine, is also called 3D letter printer, 3D signage printer, 3D logo printer, 3D printer for signages, or advertising machine for 3D signs in the signage industry, it is a specialized type of industrial 3D printer designed to fabricate three-dimensional channel letters, illuminated logos and luminous signages through additive manufacturing processes. In essence, it is an industrial 3D printer that is optimized for the large-format, durable, and visually appealing requirements of the signmakers and sign companies. It is a new, transformative and innovative tool in the sign-making and visual communications industry.

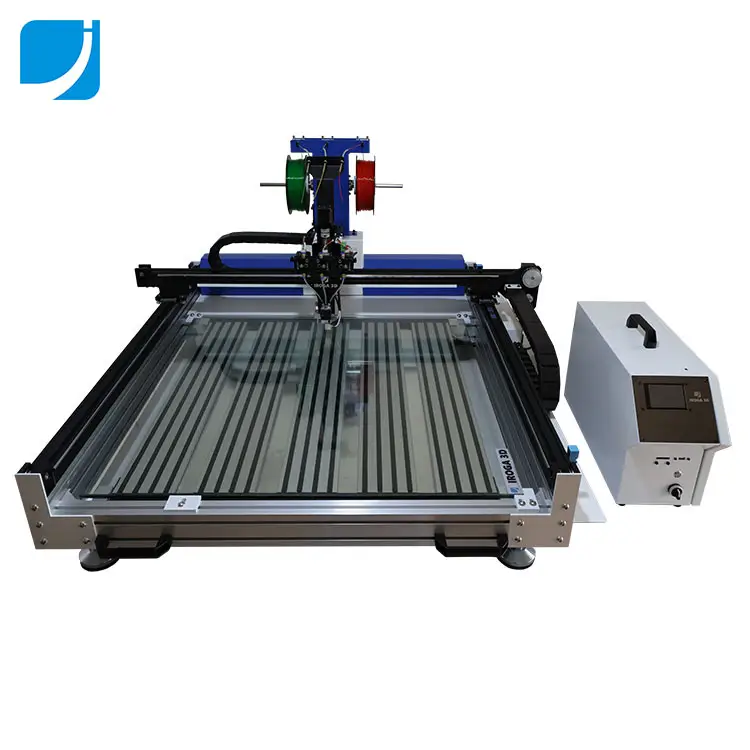

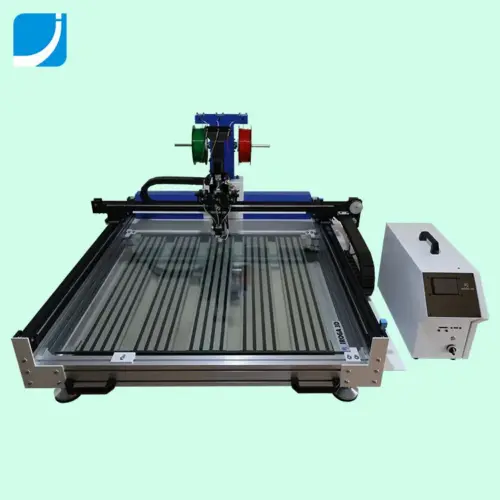

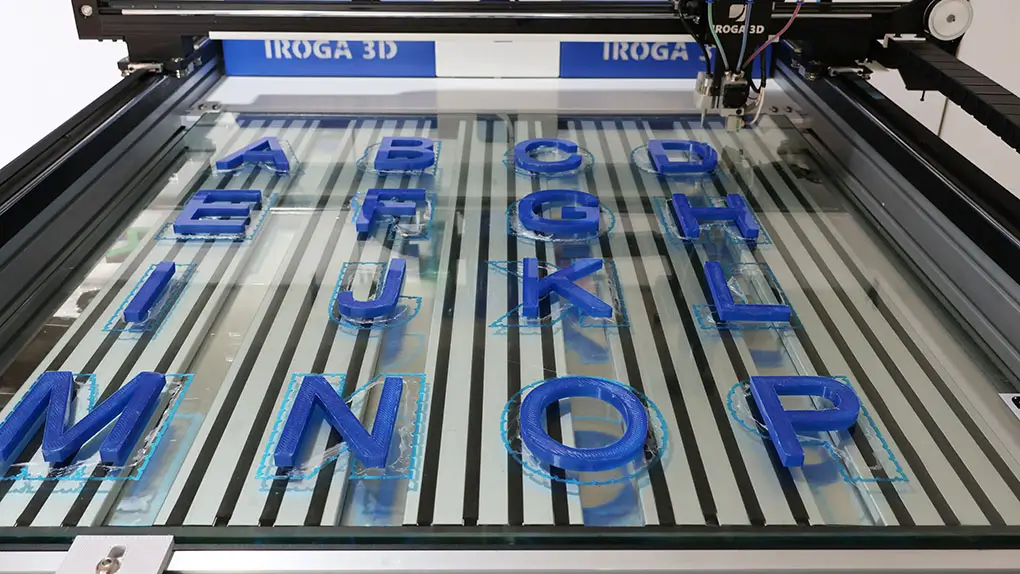

Usually, the printing sizes of 3D letter printing machines (3D letter printers) are much bigger than 3D model printers, for instance, the printing width of MITO-80 for luminous signages is as big as 32inch (800mm), and the printing depth of MITO-80 is as deep as 90mm. Unlike traditional flat printing signage or custom acrylic signage (like inkjet on vinyl), these 3D letter printing machine build 3D letters and luminous signages layer by layer from a digital file, resulting in signs with physical depth, texture, and complex geometries that are impossible to achieve with conventional methods. The 3D letter printing machine uses material which is called 3D printing filament in FDM (Fused Deposition Modeling) mode, enabling the creation of signs with width, depth, and height, both in small size and big size.

It can manufacture customized letters and signages in large quantity or small quantity as per your requirement, with multi-style or multi-color output, with illuminated sign effect or non-illuminated sign effect, and with durability for indoor and outdoor letters, internal and external signages. Common applications include 3D channel letters, brand logos and company luminous signages for storefronts, decorative and architectural elements, informational displays, and promotional advertisement. Based on CorelDRAW and Iroga 3D slicing software, 3D letter printing machines offer flexibility in design, rapid prototyping, and cost-effective production of low-volume or intricate signs, distinguishing them from subtractive manufacturing like CNC machining.

– Automatic Leveling –

– Multiple Letters Printing –

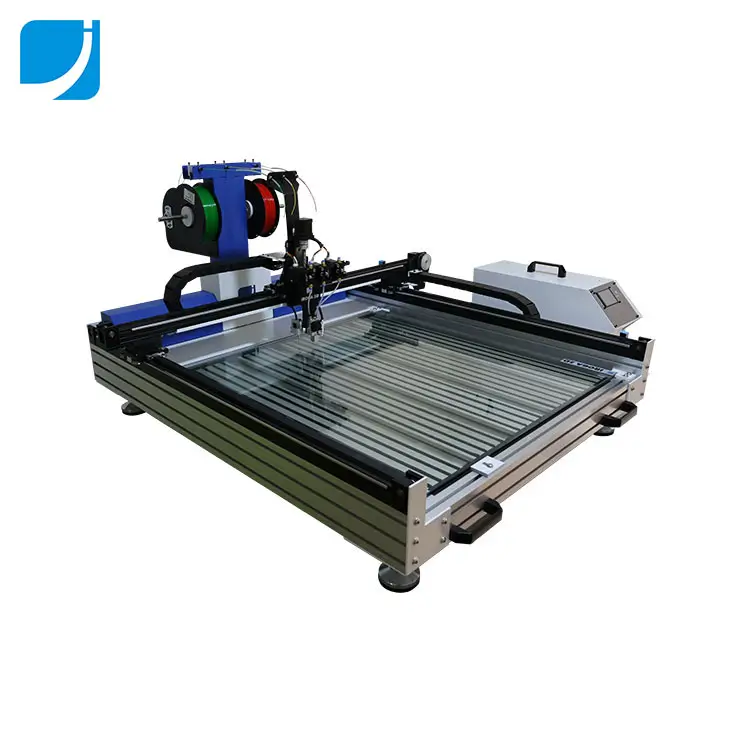

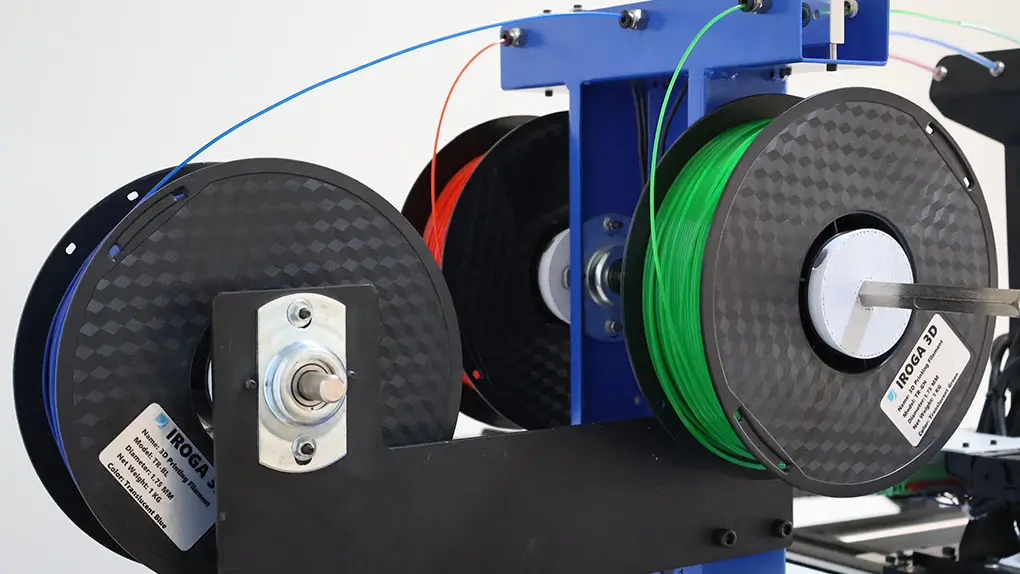

– 3 Rolls of Filament –

Nowadays, custom acrylic signs are widely used inside and outside the shops, supermarkets, malls, etc, those custom arylic signs are made in traditional way with traditional machines, such as CNC router, laser cutting machine, engraving machine, bending machine, UV curing machine, slotting machine, welding machine, etc. So why should we use 3D letter printing machines to make 3D channel letters and luminous signages? Because there are so many advantages of 3D printed signs against custom acrylic signs, including less machine investment, less space occupation, less material cost, less material waste, less labour cost, more environment friendly, longer automatic working hours, more signage styles, cleaner workshops, etc.

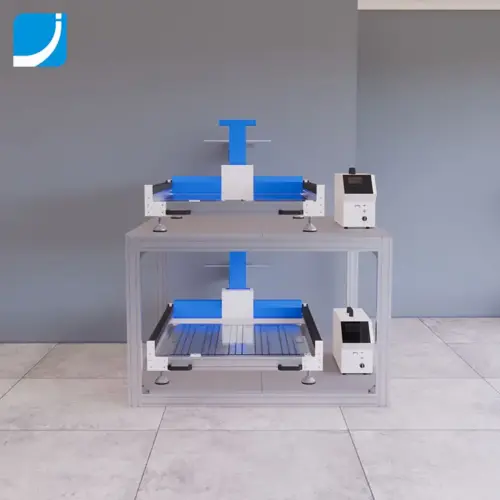

In the case of production of custom acrylic signs in the traditional way, some large machines need to work together, such as CNC router, engraving machine, bending machine, etc, it means that they have to occupy a lot of working space, as a result, it will not only add the cost of sign equipments, but also add the production cost as well, especially in the big cities where the land and houses are very expensive. 3D letter printing machines are much smaller comparing to the traditional sign machines or equipments, however, we have a further way to save the working space more, that is the 3D printer shelf, click here to know how to use 3D printer shelf appropriately.

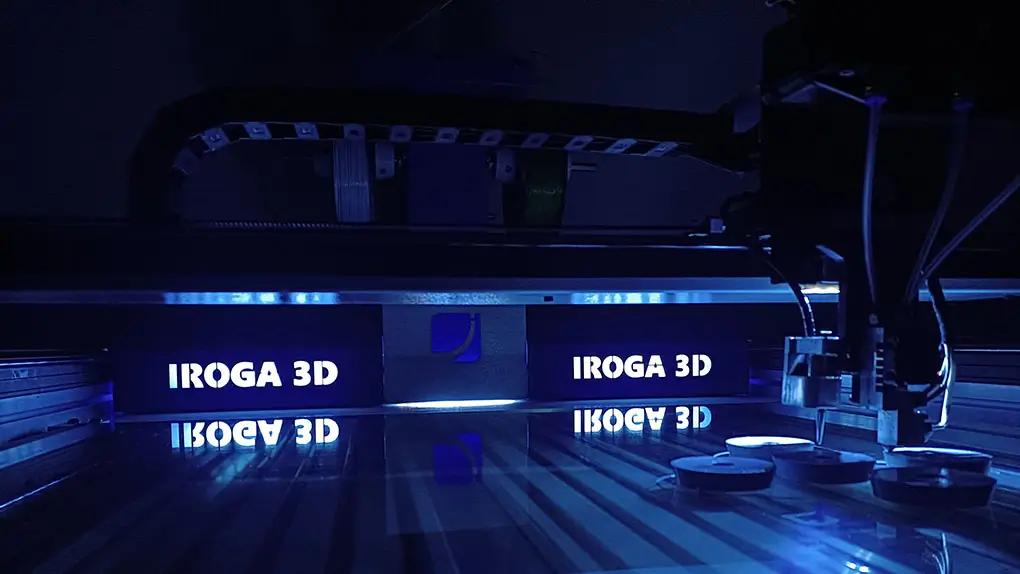

The 3D letter printing machine is made up of many different parts with different functions, for instance, the printing bed, filament rack, spool holder, XYZ axis, hot end, extruder system, printer case, etc. If you want to know more about the main structure and the crucial parts of a 3D letter printing machine, you can read this article for details, the key components of 3D letter printer. We are IROGA 3D, and our 3D letter printing machines are designed for channel letters, illuminated company logos and luminous signages.

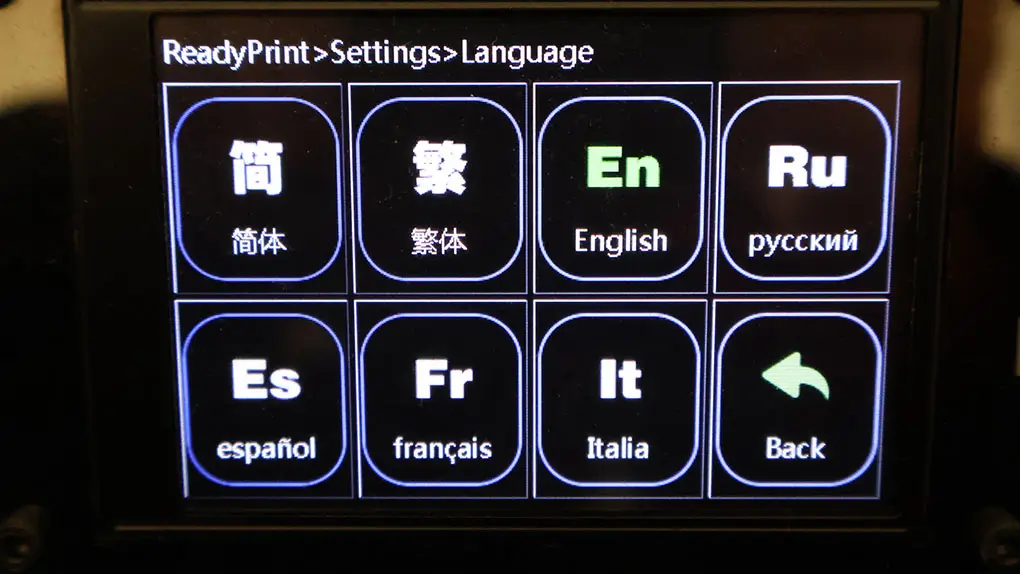

– Multiple Languages for Interface Operation –

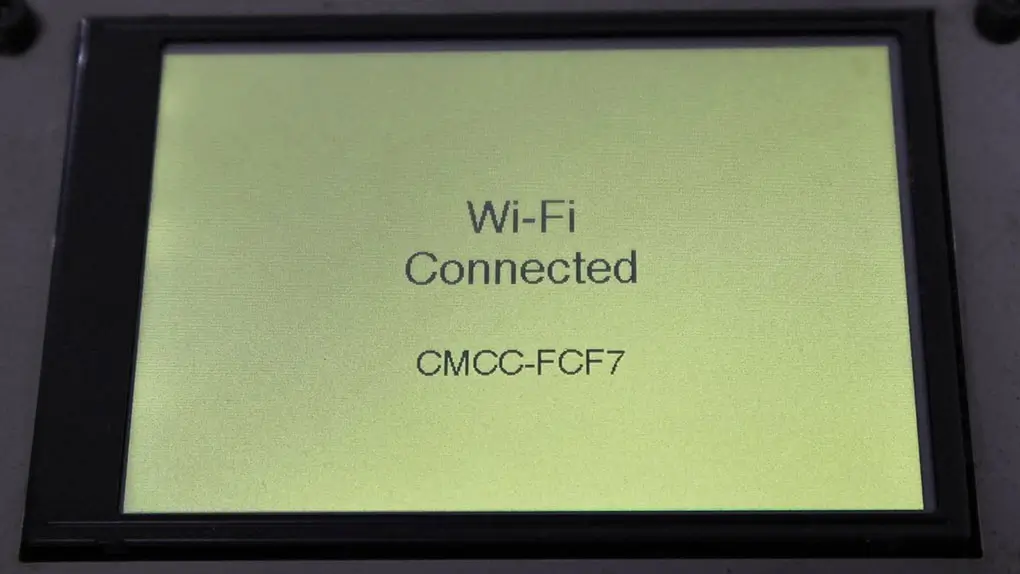

– WiFi Connection to Computer –

– Workerless Printing at Night –

Parameters of 3D Letter Printing Machine for Luminous Signages ( MITO-80 & MITO-120 )

| Item | MITO-80 | MITO-120 |

| Interface Language | EN / ES / FR / IT / RU / CN | EN / ES / FR / IT / RU / CN |

| Packaging Size | 1390 x 1340 x 870 MM | 1800 x 1700 x 870 MM |

| Printer Size | 1230 x 1100 x 700 MM | 1630 x 1500 x 700 MM |

| Maximum Printing Size | 800 x 800 x 90 MM | 1200 x 1200 x 90 MM |

| N.W. / G.W. | 95 KG / 140 KG | 130 KG / 195 KG |

| Voltage | 110 V / 220 V | 110 V / 220 V |

| Power | 720 W | 1000 W |

| Frequency | 50 HZ / 60 HZ | 50 HZ / 60 HZ |

| Printing Mode | FDM (Fused Deposition Modeling) | FDM (Fused Deposition Modeling) |

| Printing Speed | 30 ~ 100 MM/S | 30 ~ 100 MM/S |

| Platform Temperature | 50 ℃ | 50 ℃ |

| Nozzle Temperature | 230 ℃ | 230 ℃ |

| Nozzle Aperture | 0.6 MM / 0.8 MM | 0.6 MM / 0.8 MM |

| Compatible Filament | PLA / PETG / ASA / ABS | PLA / PETG / ASA / ABS |

| Filament Diameter | 1.75 MM | 1.75 MM |

| Filament Installed Quantity | 3 Rolls | 3 Rolls |

| HS Code | 8485200000 | 8485200000 |

– Customizable Brand Name –

– Customizable Brand Logo –

– 3D Printing Farm for Mass Production –

Traditional Sign Machine VS 3D Letter Printing Machine for Luminous Signages

| Item | Traditional Sign Machine | Modern 3D Sign Printer | |

| Machine Type | Bending Machine, Welding Machine, Cutting Machine, Engraving Machine, etc | One 3D Sign Printer Is Enough √ | |

| Machine Investment | More Investment | Less Investment √ | |

| Material Cost | More Expensive (Acrylic Face & Metal Side) | Less Expensive (3D Printing Filament) √ | |

| Material Waste | More Waste | Less Waste √ | |

| Manufacturing Mode | Subtractive Manufacturing | Additive Manufacturing √ | |

| Type of Work | More Manual Work | More Automatic Work √ | |

| Labor Cost | More Workers, More Cost | Less Workers, Less Cost √ | |

| Sign Face Color | Single Face Color Only | Multiple Face Colors Available √ | |

| Sign Face Style | Flat Face Only | Flat Face or Mesh Face √ | |

| Sign Side Color | Single Side Color Only | Multiple Side Colors Available √ | |

| Sign Side Style | Straight Side Only | Straight Side, Beveled Side, or Curved Side √ | |

| Sign Grade | Simple Sign Only | Simple Sign or Complicated Sign √ | |

| Illuminating Option | Frontlit or Backlit | Frontlit, Backlit, or Sidelit √ | |

| Working Space | More Space Required | Less Space Required √ | |

| Workshop | Messy | Tidy √ | |

| UV Resistance | Less UV Resistant | More UV Resistant for Longer Outdoor Use √ | |

FAQ of 3D Letter Printing Machine for Luminous Signages

| Q1: What is the MOQ of 3D sign printer ? | |

| A1: 1 set. | |

| Q2: Can the brand and color be customized ? | |

| A2: Yes, the MOQ of customization is 10 sets. | |

| Q3: What is the price term ? | |

| A3: We can deal in different price terms, for instance, EXW, FOB, CIF, DDP. | |

| Q4: What is the payment term ? | |

| A4: Usually, it will be wire transfer (telegraphic transfer), with 30% deposit and 70% balance. | |

| Q5: Can you deliver the 3D sign printer to my warehouse ? | |

| A5: Yes, we can. In this case, it will be the DDP term, we will deliver the 3D sign printers until your warehouse or workshop. | |

| Q6: How do you deliver the 3D sign printer ? | |

| A6: It can be by sea, by air, or by train, it will be up to you. | |

| Q7: How do you package the 3D sign printer ? | |

| A7: It is packaged by a fumigation free wooden box. | |

| Q8: What will you do if there's damage during delivery ? | |

| A8: We will be responsible if there's any damage during delivery, we will send new spare parts for replacement or refund. | |

| Q9: Is there any product warranty ? | |

| A9: Yes, all products from us have 18 months' quality warranty, and the technical support will be lifetime. | |

| Q10: Is there any product training ? | |

| A10: Yes, we will provide video tutorials of the machine and the software, besides, online meetings are available if required. | |

| Q11: How much is it ? | |

| A11: Feel free to contact our sales staff for prices, catalogues and any other details via Email, WhatsApp, WeChat, or telephone, we can speak Chinese, English, and Spanish (español). | |